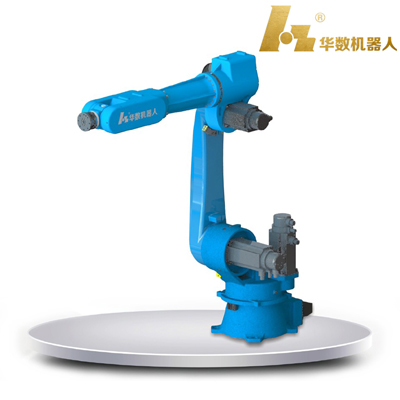

the advantage of Huashu robot

(1)System architecture: autonomously controllable

It adopts international standard EtherCAT bus technology, supports bus servo drive unit and absolute servo motor; equipped with new generation HsPad teach pendant for user teaching operation; can access industrial Ethernet such as Profinet through gateway device to realize controller and external PLC data communication;

(2) High speed and high precision control

Torque feedforward control based on dynamic modeling and accurate parameter identification;

Global intelligent trajectory optimization strategy for optimal control performance;

Multiple acceleration and deceleration strategy control and smoothing functions"

(3)safety

Simplified drag teaching based on dynamics model;

No sensor collision detection technology;

Alert mode and assist mode combined with sensors

Flexible safety zone setting and one-click return to origin;

(4)Easy to use

Debugging tools: complete parameter debugging and diagnostic tools, command-based terminal debugging;

Simulation tools: virtual control platform, 3D simulation platform;

(5)Development

A variety of secondary development interface, interacting through the command line;

Dynamic library embedding, which can load customer custom modules;

Various sensors, visual sensors, torque sensors, and stability sensors have been successfully connected.

(6)intelligent

Collaborate with Aerospace Cloud Network to develop a cloud service platform for intelligent decision-making. Based on big data analysis model and deep learning, some artificial intelligence technologies are implemented on huashu robots, such as evaluating robot health status, providing intelligent maintenance and failure warning functions for key components; Multi-sample comparison model for energy efficiency optimization during robot operation. At the same time, some interfaces of the intelligent platform will be opened for the third party to introduce the process and decision model.

(7)Process integration (customized development process package for core users)

Offline programming software

Welding process package

Gluing process package

Palletizing craft package

" Stamping process package"