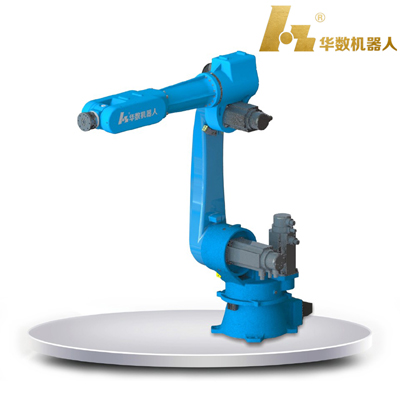

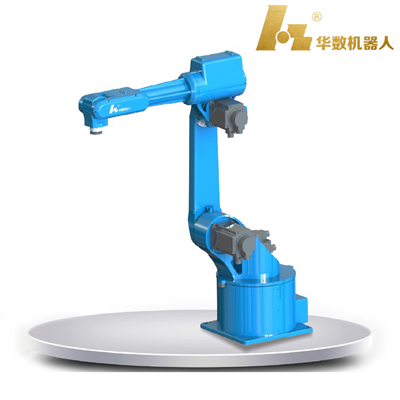

HSR-JM612 Grinding Robot

"At present, the universal robots in the 3C grinding industry are difficult to adapt to the harsh working conditions such as repeated impact loads in the grinding process, dusty working environment (dry hit) and high humidity (water hit). So in order to provide customers a sustainable and stable production capacity and create higher return, we have created the HUASHU HSR-JM612 which is specifically optimized for the grinding process, which also will bring you a perfect 3C grinding solution.

Characteristics

Strong ontology performance

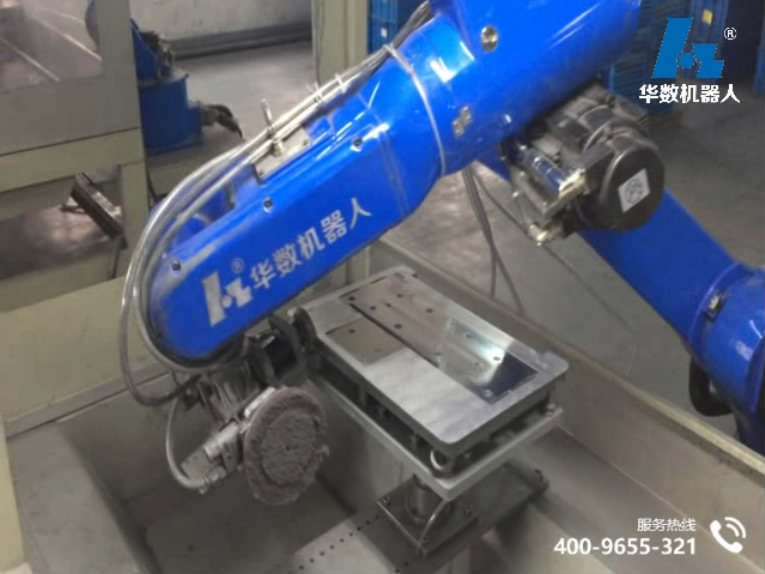

1.High protection: In order to solve the problem with dust and liquid splashing during grinding, the robot arm and wrist protection level reaches IP65 as to prevent damage to the robot body caused by intruding objects.

2.Enhanced load design: In order to cope with the repeated impact of the grinding force on the robot during the grinding process, we have enhanced the design of the larger key parts of facing the impact of the robot to ensure the service life.

3.High stiffness: After enhancing the design of the forearm, the forearm can provide sufficient stiffness to cope with the impact from grinding as well as can ensure the accuracy of the trajectory and the retention of the grinding precision during the grinding process, thus, providing a long-lasting high quality grinding process.

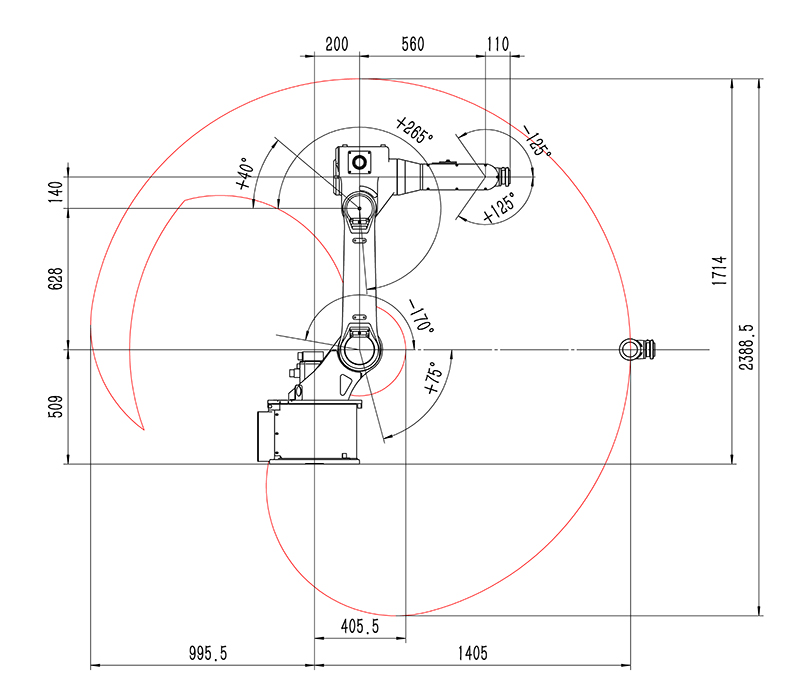

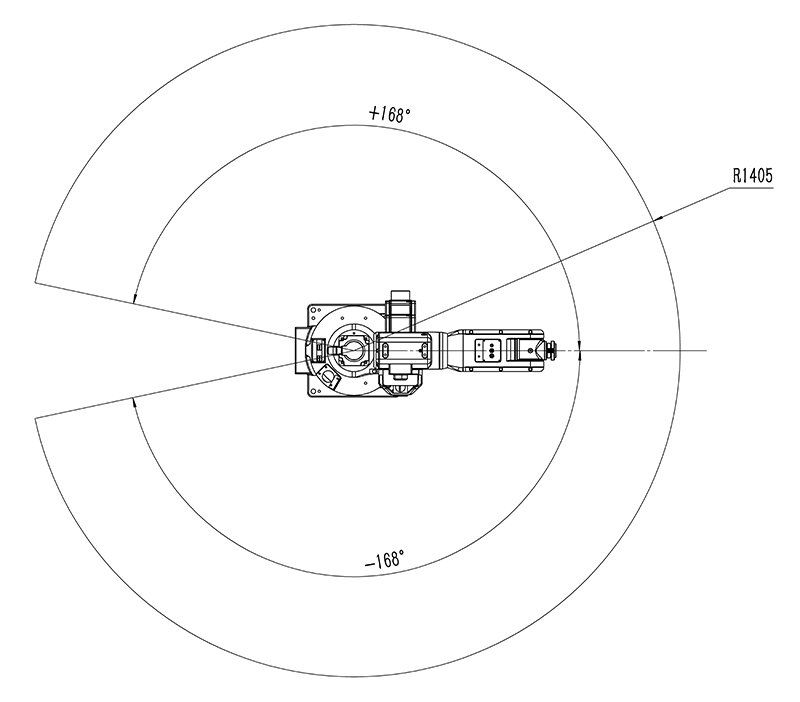

4. High precision: absolute positioning accuracy reaches ±0.4mm, repeat positioning accuracy is ±0.06mm, which reduces the error of offline programming and actual grinding track, shortens production debugging cycle and reduces debugging difficulty.

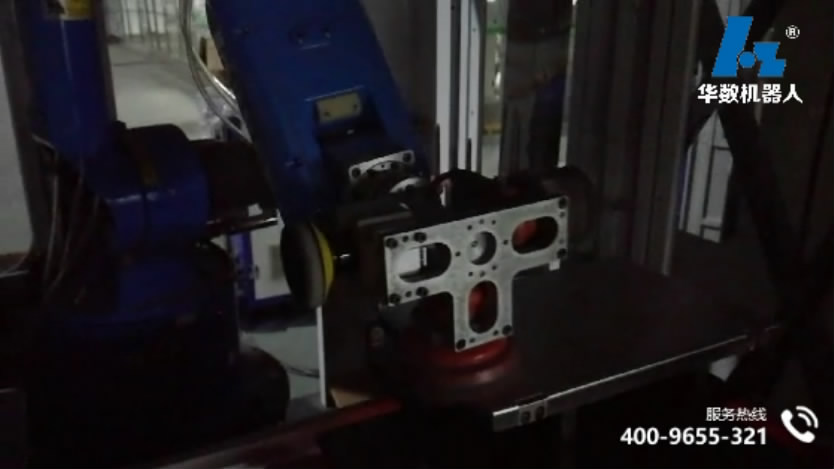

5.Fully space utilization: Due to the needs of grinding workpiece size and process requirements, we have optimize the robot arm span specifically for 3C which can reduce the occupied area, improve the space utilization rate and increase the layout density under most of the workpiece grinding process.

Grinding dedicated offline programming software

The grinding offline programming software developed by Chongqing HUASHU Robot has the characteristics of “quick programming and precisely attainable.” It integrates professional application technology, and it is easy to get started quickly. It also combines with the supporting precision compensation system to achieve the tracking of operating motion. The lower the difficulty of trajectory programming, the shorter the production debugging cycle.

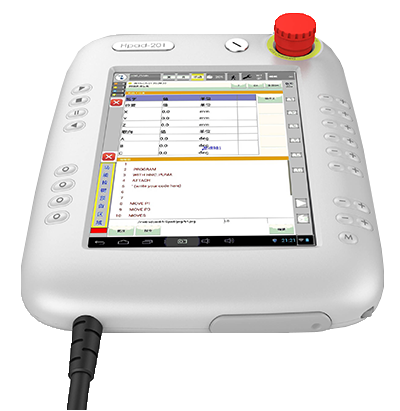

User-Friendly Open Solaris

Huazhong CNC independent research and development control system has strong usability in the industry, and through the high-speed transmission of EtherCAT bus for data communication, the system can complete circular arc interpolation motion with multi-axis linkage. Friendly to operate and easy to understand.

Industrial Robot Solution