Can carry out training projects

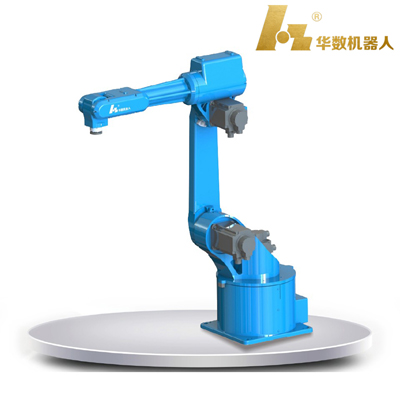

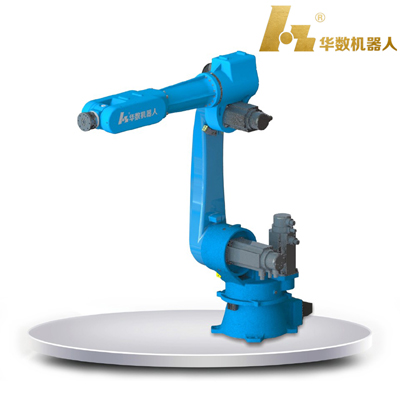

Industrial robot I/O setting practical training

Industrial robot workpiece grabing and handling practical training

Industrial Robot feeding and blanking practical training

Off-line programming practical training

Industrial robot carving application comprehensive practical training

Industrial robot spraying application comprehensive practical training

Industrial robot workpiece grabing and handling practical training

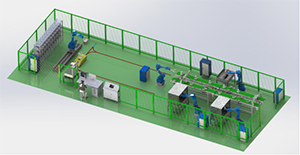

Industrial robot and automatic transmission line integrated positioning practical training

Integration of industrial robot and AGV with automatic feeding and blanking, positioning practical training

Industrial robot and PLC electrical control system integration practical training

Industrial robot feeding and blanking integrated practical training

Industrial robot positioning practical training

Debugging and practical training of the seventh axis of robot

Comprehensive practical training on intelligent storage of industrial robots

Visual detection system sensor and light source type selection, installation, debugging practical training

Visual image input editing and debugging

editing and debugging based on Visual results

practical training of Image detection system of visual sorting robot application

Industrial robot and automatic transmission line data communication practical training

Industrial robot and automatic transmission line integrated positioning practical training

PLC electrical control system integration practical training

Industrial robot automatic feeding and blanking integrated practical training

Industrial robot automatic transmission, feeding and blanking integrated practical training

practical training of RFID and general control communication building and setting

practical training of Simulate MES system setup

practical training of Workpiece RFID automatic identification installation and adjustment

practical training of Installation and wiring training of general control system

practical training of RFID data transmission communication Settings and network construction

practical training of joint debugging of the general control system and each workstation coordinate

practical training of Industrial robot and PLC electrical control system integration